1

/

of

8

FOHERE

FOHERE Commercial Cotton Candy Machine, 1000W Cotton Candy Maker Machine, Candy Floss Maker with Stainless Steel Bowl, and Sugar Scoop,for Family Party, Kids Birthday Red

FOHERE Commercial Cotton Candy Machine, 1000W Cotton Candy Maker Machine, Candy Floss Maker with Stainless Steel Bowl, and Sugar Scoop,for Family Party, Kids Birthday Red

Regular price

$259.99 USD

Regular price

Sale price

$259.99 USD

Unit price

/

per

Couldn't load pickup availability

【Professional-Grade Performance】Engineered with a 1000W optimized heating system, our commercial cotton candy machine delivers industrial-level productivity. The precision thermal control maintains optimal operating temperatures for 60+ minutes of continuous operation, enabling bulk production without performance degradation or maintenance interruptions. This operational endurance ensures reliable throughput for high-demand commercial environments.

- 【Versatile Candy Processing Capability】Designed as a universal sugar conversion platform, this unit accommodates diverse confectionery inputs including crystalline floss sugars, compressed milk sugars, fruit-flavored cubes, and standard hard candies. Its space-efficient footprint (20" bowl diameter) facilitates deployment across multiple revenue channels: mobile food kiosks, stadium concessions, event catering services, and amusement venue operations.

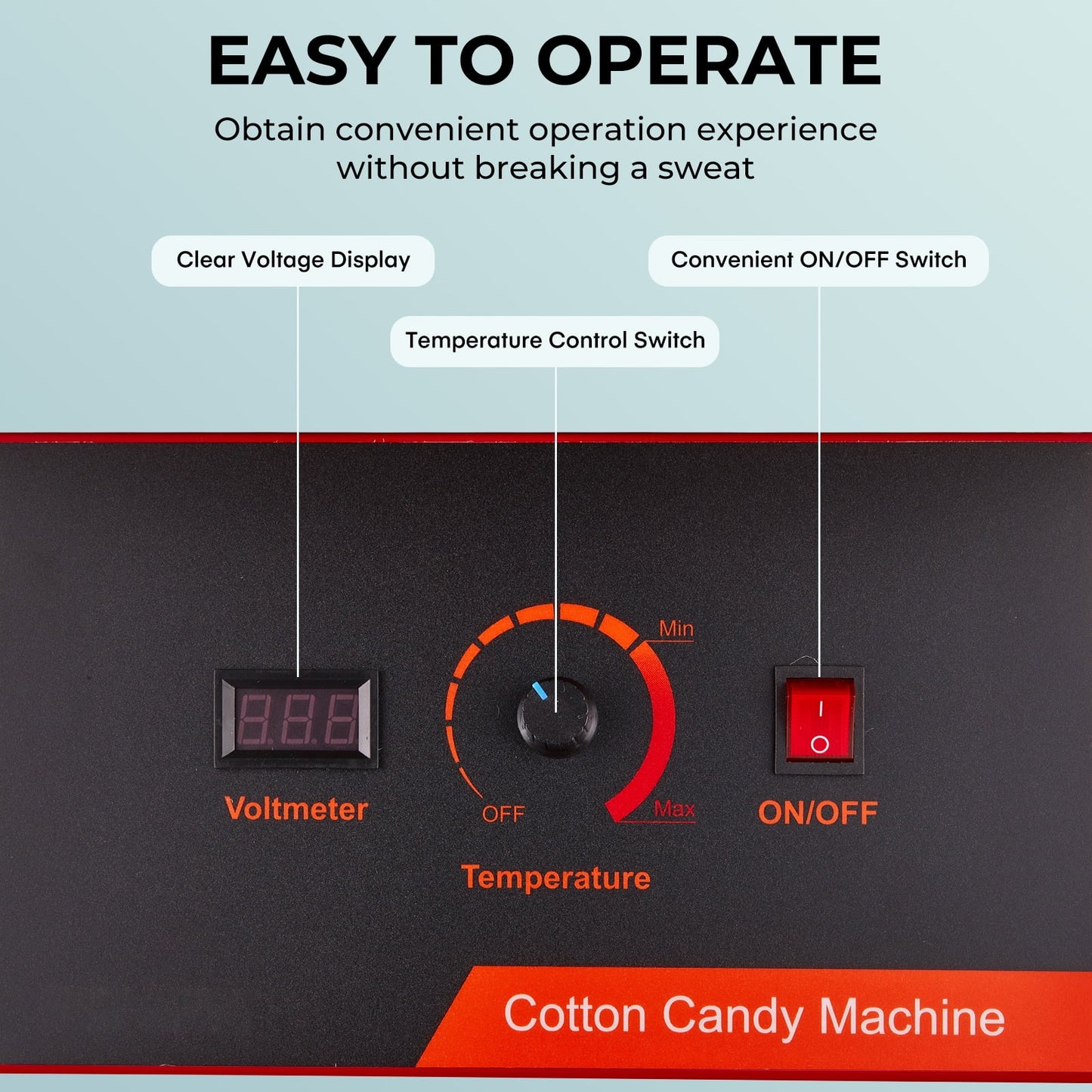

- 【Industrialized Simplicity】The dual-switch control architecture (separate power/heat circuits) streamlines operational workflows. Activation sequence: 1) Engage both master switches 2) Achieve thermal equilibrium (4-6 minute warmup) 3) Introduce raw material via included sugar scoop 4) Initiate centrifugal fiberization. Operator interaction reduces to simple stick rotation for web collection - no technical expertise required.

- 【Heavy-Duty Food Machinery Construction】Military-specification build quality combines 14-gauge carbon steel chassis with commercial-grade 304 stainless steel processing bowl. Reinforced weld points and anti-corrosion coating withstand rigorous daily sanitation protocols and 18-hour operational cycles. Exceeds NSF/ANSI food equipment durability standards for commercial foodservice applications.

- 【Thermal Management Engineering】The cross-ventilation system incorporates dual lateral heat dissipation arrays with copper alloy heat sinks, maintaining critical component temperatures 23% below industry averages during continuous operation. Non-marking vibration-dampened base stabilizers prevent surface migration during high-RPM cycles. Bonus professional toolkit includes FDA-compliant sugar measure and stainless steel scraping instruments.

Share